Investing in Manufacturing

Efficiency and waste reduction are both key elements of running a successful manufacturing operation. There’s only so far great processes can take you without the right equipment for a growing business without investment in faster and better equipment.

Scotts Timber Engineering is bucking trends in the sector and experiencing volume growth as a result of its approach, and as a result, the next logical step is to upgrade the machinery we depend on in the factory to improve productivity.

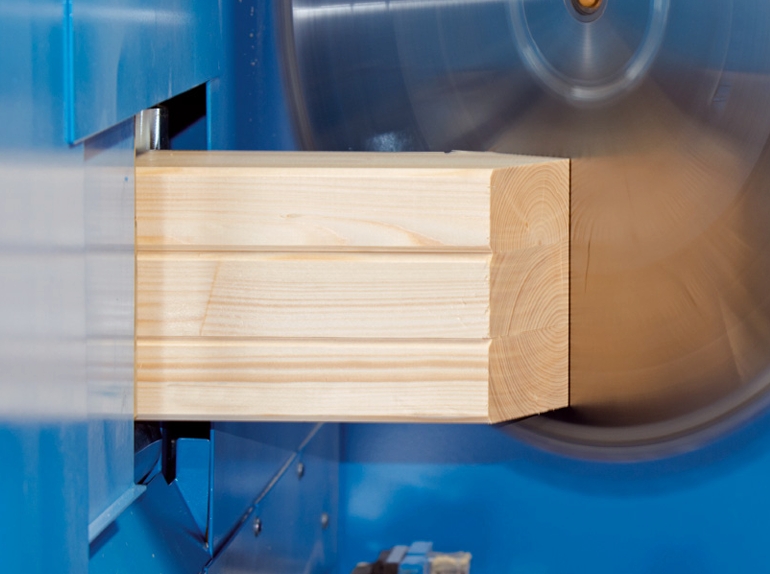

As a result, we have invested in an additional, new Hundegger Turbo-Drive 450 saw, a high performance cutting machine that can cut three times as much timber in a day as some of our current equipment and will also help our teams optimise cutting lists and reduce offcut wastage dramatically.

Process Manager Roxanne Newton is running the project that will plan and oversee the delivery and installation of the new saw at our Northamptonshire factory in February as well as the integration with our operational systems. “Changing such a fundamental piece of equipment is a big project with lots of moving parts,” she explained when asked about the challenges. “However, our team can all see the benefits and are very supportive of the project team as we move closer to installation.”

Follow us for updates on the installation early in 2025!